03.27.23

Melodea, Ltd., a producer of sustainable barrier coatings for packaging, launched VBseal, a new sustainable packaging solution that the company said can be used as an alternative to plastic.

The green coating solution is resistant to water vapor, oil, aroma, and has heat-sealing properties. The company brought its first products to market, MelOx and VBcoat, last year. VBseal is resistant to water vapor, oil, aroma, and has heat-sealing properties.

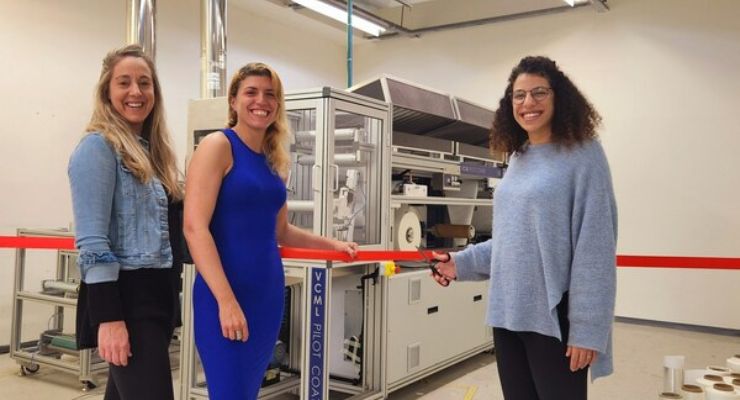

The company has also launched a pilot plant and innovation center, allowing it to serve its customers as well as to demonstrate the new solution. The new site will also test out the company’s existing barrier coating products and produce coated reels and pouches at pilot scale.

Citing a report by the Back to Blue initiative, the amount of plastic used around the world could almost double by 2050 unless urgent action is taken, Melodea reports. Without significant policy interventions, it is expected that the amount of plastics consumed across the G20 nations will surpass 450 million tons per year by that date, which is nearly twice the most recently measured 2019 level of 261 million tons.

A global ban on unnecessary single-use plastic items will be the most effective policy, according to the report. In March 2022, 175 nations agreed to work together on a United Nations treaty to reduce plastic pollution, and it is expected to be in place by the end of 2024.

VBseal

VBseal has high resistance to water vapor and heat-sealing properties, all in one coating. It joins Melodea’s existing eco-friendly barrier coating products, MelOx for oxygen and VBcoat for water vapor, oil, and grease. The products were developed using cellulose nanocrystals, a forestry byproduct which is biodegradable, fully recyclable, and non-toxic.

The VBseal material is designed to line packaging of fresh foods, cereals, fast foods, confectionery such as biscuits and ice cream, detergents, and cosmetics. It is fully recyclable, provides high-performance protection, and, in coating machines, offers a single product for both water vapor and heat sealing, avoiding the need for two different passes in coating machines. This makes it easy to apply and can reduce production costs, according to the company.

The VBseal is free of paraformaldehyde (PFA) and bisphenol A (BPA), and is FDA and BfR-compatible.

“Packaging producers have an urgent need for a sustainable barrier coating that has both water vapor protection and heat sealable properties and can replace the commonly used plastic PE layer,” said Cee Azerraf, PhD, VP of sales and marketing at Melodea. “Our R&D team worked on this new product joining our existing VBcoat and, as with all of our products, it was crucial that it be recyclable and easy to apply on existing coating lines.”

New Pilot Plant

Melodea has opened a new pilot center and invested $500,000 in advanced equipment and analytics tools to support CPG companies and packaging producers to meet sustainability goals in green packaging. The new center will serve companies looking to explore sustainable barrier solutions for plastic, paper, and bioplastics.

“We offer our clients a location to evaluate their products using our eco-friendly solutions, with full control of the coating process,” said Shaul Lapidot, PhD, CEO and co-founder of Melodea. “We can utilize Melodea’s R&D team’s vast know-how of coatings with optimizing barrier performance, and analyze the results on site, as well as help shorten time-to-market for new products and packages.”

Many large CPG companies have made commitments to have 100% recyclable or reusable packages within a short window of time. “We are excited to work with producers of food, cosmetics, pharmaceutical, and agricultural products as well as packaging companies at the new plant to help them reach their goals,” said Lapidot.

The green coating solution is resistant to water vapor, oil, aroma, and has heat-sealing properties. The company brought its first products to market, MelOx and VBcoat, last year. VBseal is resistant to water vapor, oil, aroma, and has heat-sealing properties.

The company has also launched a pilot plant and innovation center, allowing it to serve its customers as well as to demonstrate the new solution. The new site will also test out the company’s existing barrier coating products and produce coated reels and pouches at pilot scale.

Citing a report by the Back to Blue initiative, the amount of plastic used around the world could almost double by 2050 unless urgent action is taken, Melodea reports. Without significant policy interventions, it is expected that the amount of plastics consumed across the G20 nations will surpass 450 million tons per year by that date, which is nearly twice the most recently measured 2019 level of 261 million tons.

A global ban on unnecessary single-use plastic items will be the most effective policy, according to the report. In March 2022, 175 nations agreed to work together on a United Nations treaty to reduce plastic pollution, and it is expected to be in place by the end of 2024.

VBseal

VBseal has high resistance to water vapor and heat-sealing properties, all in one coating. It joins Melodea’s existing eco-friendly barrier coating products, MelOx for oxygen and VBcoat for water vapor, oil, and grease. The products were developed using cellulose nanocrystals, a forestry byproduct which is biodegradable, fully recyclable, and non-toxic.

The VBseal material is designed to line packaging of fresh foods, cereals, fast foods, confectionery such as biscuits and ice cream, detergents, and cosmetics. It is fully recyclable, provides high-performance protection, and, in coating machines, offers a single product for both water vapor and heat sealing, avoiding the need for two different passes in coating machines. This makes it easy to apply and can reduce production costs, according to the company.

The VBseal is free of paraformaldehyde (PFA) and bisphenol A (BPA), and is FDA and BfR-compatible.

“Packaging producers have an urgent need for a sustainable barrier coating that has both water vapor protection and heat sealable properties and can replace the commonly used plastic PE layer,” said Cee Azerraf, PhD, VP of sales and marketing at Melodea. “Our R&D team worked on this new product joining our existing VBcoat and, as with all of our products, it was crucial that it be recyclable and easy to apply on existing coating lines.”

New Pilot Plant

Melodea has opened a new pilot center and invested $500,000 in advanced equipment and analytics tools to support CPG companies and packaging producers to meet sustainability goals in green packaging. The new center will serve companies looking to explore sustainable barrier solutions for plastic, paper, and bioplastics.

“We offer our clients a location to evaluate their products using our eco-friendly solutions, with full control of the coating process,” said Shaul Lapidot, PhD, CEO and co-founder of Melodea. “We can utilize Melodea’s R&D team’s vast know-how of coatings with optimizing barrier performance, and analyze the results on site, as well as help shorten time-to-market for new products and packages.”

Many large CPG companies have made commitments to have 100% recyclable or reusable packages within a short window of time. “We are excited to work with producers of food, cosmetics, pharmaceutical, and agricultural products as well as packaging companies at the new plant to help them reach their goals,” said Lapidot.