Patrick Morris, Communications Manager, Fortitech Inc.08.15.13

Nutrient premixes are used in a variety of applications by food, beverage and pharmaceutical manufacturers throughout the world. They offer numerous benefits, which include streamlining the production process by providing a single source of multiple nutrients. Additionally, manufacturers will experience savings on labor, inventory and testing. Premixes also offer greater consistency and help address issues surrounding product taste and texture early in the development stage. Use of a premix greatly reduces the chance of incorrectly weighing materials during the manufacturing process of a finished product. All of these potential errors can be avoided by using a custom nutrient premix.

In speaking with Fortitech’s Supervisor, Senior Formulations Scientist, Cathy Arnold, I touched on the concept of overages within our premixes. This is what she had to say:

Important technical aspects that need to be considered when creating food and beverage premixes are the choice of carrier, nutrient interactions, bioavailability of nutrients and stability of nutrients relative to their storage and processing conditions. A well formulated product should not cause adverse effects to the product’s taste, color or other nutrients.

The stability of the individual vitamins varies from the relatively stable, such as niacin, to the highly unstable, such as vitamins B1 A and C. The factors that affect the stability vary from vitamin to vitamin. The most important of these factors are heat, moisture, oxygen, pH and light.

The degradation of vitamins can take place naturally during storage, processing and preparation of finished foods and interactions with other components of foods. The factors that affect the degradation of vitamins are the same, whether the vitamins are endogenous in foods, or are added as fortificants. Minerals are generally stable, however, the presence of copper and iron, for example, may have an impact on vitamin stability.

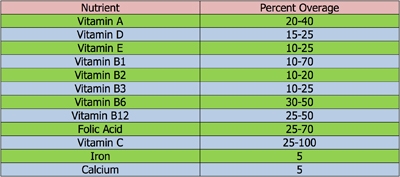

Because of the stability issues mentioned above, one has to incorporate appropriate overages during the development phase of a food or beverage. Overages are determined for each end application, based on processing and shelf life requirements, along with internal historical experience and nutrient stability data.

Vitamins do not degrade at the same rate in a food at any set of conditions, therefore no one can give an exact percentage loss. However, based on our experience, suggested overages for some of the selected nutrients in general (subject to finished products, processing conditions, etc.) are as follows:

Even with added precautions and adding overages to ensure the micronutrient levels in foods and beverages, some losses can occur during distribution and storage. Proper storage conditions and appropriate packaging can reduce micronutrient loss during distribution. For more information, visit www.fortitech.com.

In speaking with Fortitech’s Supervisor, Senior Formulations Scientist, Cathy Arnold, I touched on the concept of overages within our premixes. This is what she had to say:

Important technical aspects that need to be considered when creating food and beverage premixes are the choice of carrier, nutrient interactions, bioavailability of nutrients and stability of nutrients relative to their storage and processing conditions. A well formulated product should not cause adverse effects to the product’s taste, color or other nutrients.

The stability of the individual vitamins varies from the relatively stable, such as niacin, to the highly unstable, such as vitamins B1 A and C. The factors that affect the stability vary from vitamin to vitamin. The most important of these factors are heat, moisture, oxygen, pH and light.

The degradation of vitamins can take place naturally during storage, processing and preparation of finished foods and interactions with other components of foods. The factors that affect the degradation of vitamins are the same, whether the vitamins are endogenous in foods, or are added as fortificants. Minerals are generally stable, however, the presence of copper and iron, for example, may have an impact on vitamin stability.

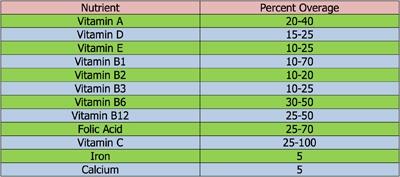

Because of the stability issues mentioned above, one has to incorporate appropriate overages during the development phase of a food or beverage. Overages are determined for each end application, based on processing and shelf life requirements, along with internal historical experience and nutrient stability data.

Vitamins do not degrade at the same rate in a food at any set of conditions, therefore no one can give an exact percentage loss. However, based on our experience, suggested overages for some of the selected nutrients in general (subject to finished products, processing conditions, etc.) are as follows:

Even with added precautions and adding overages to ensure the micronutrient levels in foods and beverages, some losses can occur during distribution and storage. Proper storage conditions and appropriate packaging can reduce micronutrient loss during distribution. For more information, visit www.fortitech.com.